3 7/8 * pi * 3 21/32 = 44.487 cubic inch displacement in one cylinder bore. Since I didn't want to buy Premium fuel, 8.7:1 is right about where I wanted to be.ģ 7/8" bore, 3 21/32" stroke. Some math was involved that resulted in a new compression ratio of 8.6:1 without milling the heads. Stock steel shim) which would reduce the combustion chamber volume and raise the compression ratio. This would remove the same amount of material as the new composite head gaset, leaving. It was determined that I would have the block machined ("decked"). The 345 started out at 8.28:1 according to the factory.

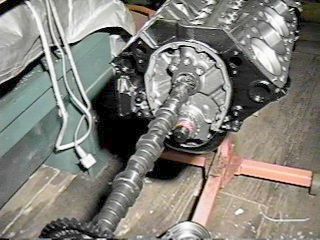

018" thick compressed, while the composite gaskets hover around. There is an important distinction between the two - the stock gasket is. When the engine kit arrived, it contained a composite head gasket. I ordered a Deluxe Head Porting kit from Summit Racing to begin porting my own heads. Gryphin Racing provided the Iskendarian 262 duration camshaft, lifters,Īnd valve springs. 030 over re-ring kit, upgraded to single moly rings,Īdded Federal Mogul Sterling H997CP hypereutectic pistons with teflon coated skirts (.030), an oil-pump rebuild kit, and timing gear set. Northern Auto Parts was contacted and the engine rebuild components were ordered. The miscellaneous pieces were retrieved from the machinist. TheĬylinder bores were first checked for original piston reuse and found unsatisfactory. The crank was magnafluxed and checked for wear - it was within standard sized bearing tolerance. I began by taking the bare block, crank, timing cover, water pump housing, valley/tappet cover, etc to the machinist. Note that at this point, I should have opted to buy a 392 short-block core from the junkyard - building a 392 is somĮthing on the order of $20 more than building a 345. When it came time to start the rebuild, however, slight rust pitting was found in the cylinder walls which required going to an overbore. It had been disassembled and was believed to be in sufficiently good condition that a simple re-ring operation was all that was necessary.

The engine was purchased in March of '99 for $80. I later found out I had overheated the 304 in TiggerĪnd thus, I began in earnest the rebuild of my very first engine, a 1977 International Harvester 345V8. It was replaced with a borrowed 345 while in Denver so I could return home. My '77 Scout II "Tigger." On August 5th, arriving in Denver (900 miles from home), the motor began to lose power. I put my spare 304 in, and towed the Little Devil to the Rocky Mountain IH Rendezvous in Denver, Colorado, behind On July 5th, 1999, I overheated and killed (took out a few bearings among other things) the '77 304V8 in my race Scout II ("Little Devil"). Building a Performance IH 345 - Part 1 Building a Performance IH 345 - Part 1

0 kommentar(er)

0 kommentar(er)